Project Description

Technical data

AUSTFIXS GLASS FIXINGS ASSEMBLY

1. SWIVEL BALL JOINT TYPE: The swivel articulated joint type is fixed to the countersunk hole in the glass with a stainless steel countersunk swivel head secured to a threaded disc. The screw fixing unit is clamped to the glass hole and fastened on to the supporting stainless steel spider arm behind the glass panel.

Tests show that the swivel joint fixing on the glass panel is free to rotate at 10 degree angle in any direction and laboratory tests show that the actual stress around the glass hole is reduced to 70% compared to the standard conventional fixing type.

Glass panels fixed with swivel joint expect to deflect more than the glass panel fixed with standard conventional type.

2. THE STANDARD COUNTERSUNK-HOLE TYPE: The standard conventional countersunk hole is drilled on the glass panel and a countersunk nylon bush used in conjunction with a countersunk socket head screw which is fixed through the glass to the energy absorbing supporting stainless steel plate or beam behind the glass panel. Tests show that the countersunk holes in the glass together with the nylon bush and countersunk socket head screw provides a total rotation of 4 degrees in any direction.

The laboratory tests show that when the glass panel is fixed with 4 or more point Austvision stainless steel supports the actual applied stress on the glass holes is 40% less than the theoretical calculated stress.

Austvison M10 fixing assembly with a spring washer and AGA nut

When fixing Austvision 445 series spider to steel or glass fin support structures to support lateral loads from wind the M10 AGA nut, spring washer and washer fixing are hand tightened to compress the spring washer to approximately 75% of flat.

This can be achieved by hand tightening using your fingers then a tweak with an allen key or by using a torque wrench to about 4 Nm (3 ft/Ibs). At 4 Nm the AGA nut will be difficult to undo by hand.

We advise tightening by hand during installation and then using a torque wrench to set all fixings for uniformity.

This also applies to the M10 spider to glass connection.

Austvsion M14 swivel fixing with spring washer and AGA Nut

For M14 swivels fittings the M14 AGA nut can be hand tightened to compress the spring washer to approximately 75% of flat.

This can be achieved by hand tightening using your fingers then a tweak with an allen key or by using a torque wrench to about 5 Nm (3.7 ft/Ibs). At 4 Nm and above the AGA nut will be difficult to undo by hand

We advise tightening by hand during installation and then using a torque wrench to set all fixings for uniformity.

Note – 1Nm= 0.73 ft/lbs

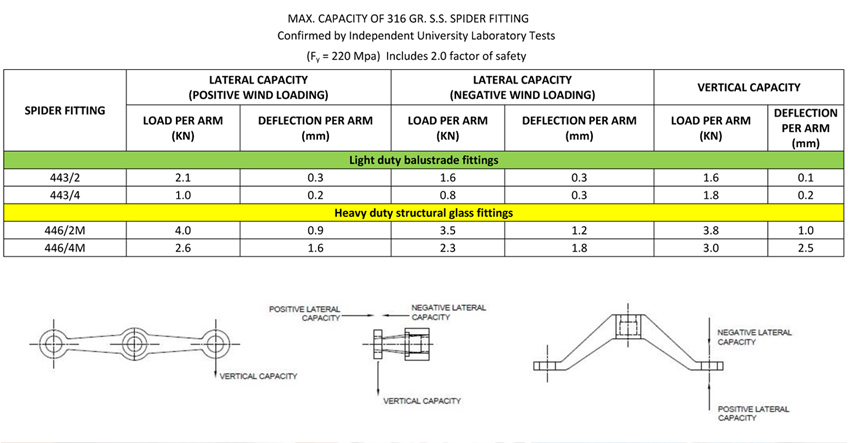

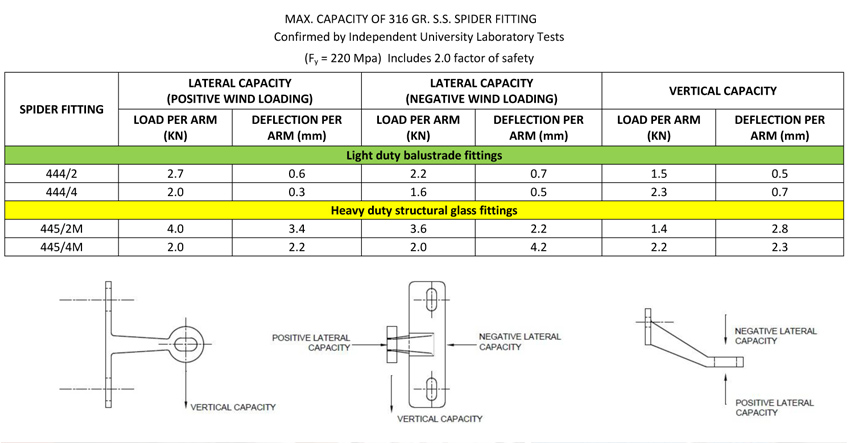

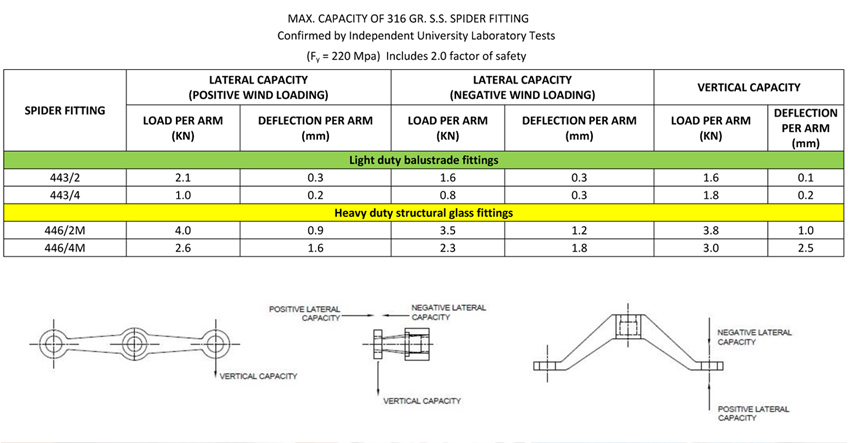

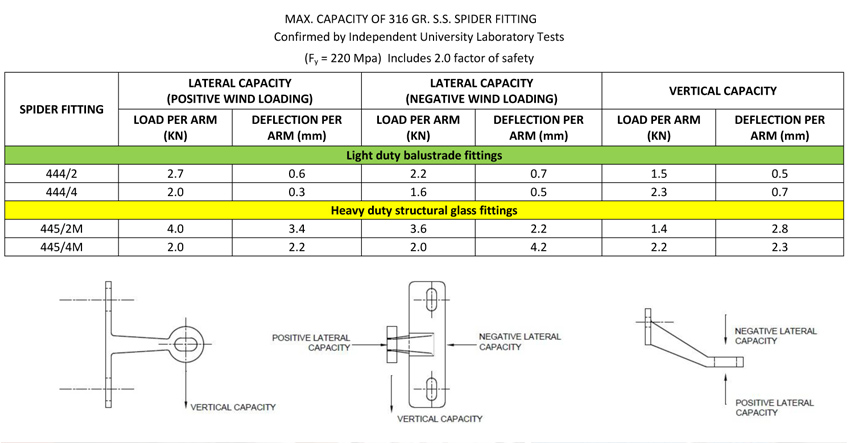

Max Capacity of 316 gr. S.S. Spider Fitting

Technical data

AUSTFIXS GLASS FIXINGS ASSEMBLY

1. SWIVEL BALL JOINT TYPE: The swivel articulated joint type is fixed to the countersunk hole in the glass with a stainless steel countersunk swivel head secured to a threaded disc. The screw fixing unit is clamped to the glass hole and fastened on to the supporting stainless steel spider arm behind the glass panel.

Tests show that the swivel joint fixing on the glass panel is free to rotate at 10 degree angle in any direction and laboratory tests show that the actual stress around the glass hole is reduced to 70% compared to the standard conventional fixing type.

Glass panels fixed with swivel joint expect to deflect more than the glass panel fixed with standard conventional type.

2. THE STANDARD COUNTERSUNK-HOLE TYPE: The standard conventional countersunk hole is drilled on the glass panel and a countersunk nylon bush used in conjunction with a countersunk socket head screw which is fixed through the glass to the energy absorbing supporting stainless steel plate or beam behind the glass panel. Tests show that the countersunk holes in the glass together with the nylon bush and countersunk socket head screw provides a total rotation of 4 degrees in any direction.

The laboratory tests show that when the glass panel is fixed with 4 or more point Austvision stainless steel supports the actual applied stress on the glass holes is 40% less than the theoretical calculated stress.

Austvison M10 fixing assembly with a spring washer and AGA nut

When fixing Austvision 445 series spider to steel or glass fin support structures to support lateral loads from wind the M10 AGA nut, spring washer and washer fixing are hand tightened to compress the spring washer to approximately 75% of flat.

This can be achieved by hand tightening using your fingers then a tweak with an allen key or by using a torque wrench to about 4 Nm (3 ft/Ibs). At 4 Nm the AGA nut will be difficult to undo by hand.

We advise tightening by hand during installation and then using a torque wrench to set all fixings for uniformity.

This also applies to the M10 spider to glass connection.

Austvsion M14 swivel fixing with spring washer and AGA Nut

For M14 swivels fittings the M14 AGA nut can be hand tightened to compress the spring washer to approximately 75% of flat.

This can be achieved by hand tightening using your fingers then a tweak with an allen key or by using a torque wrench to about 5 Nm (3.7 ft/Ibs). At 4 Nm and above the AGA nut will be difficult to undo by hand

We advise tightening by hand during installation and then using a torque wrench to set all fixings for uniformity.

Note – 1Nm= 0.73 ft/lbs

Max Capacity of 316 gr. S.S. Spider Fitting